Executive Summary

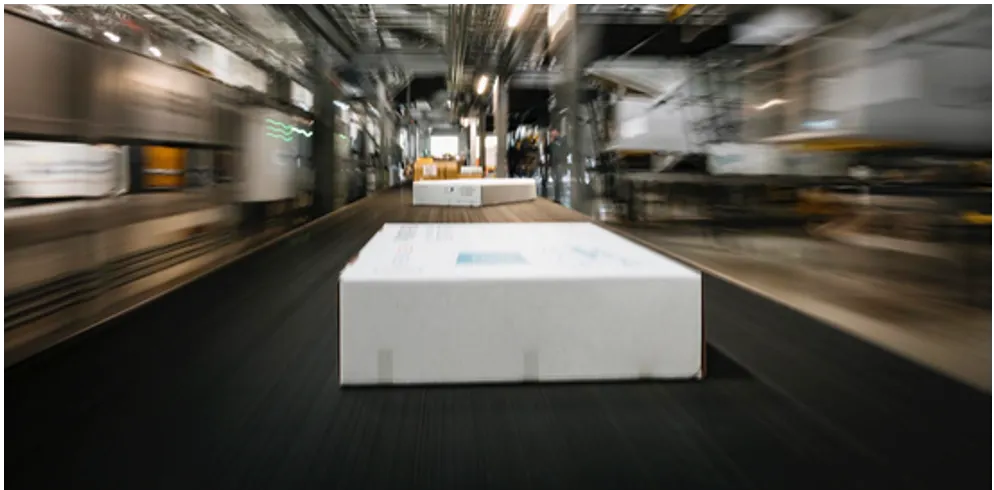

As companies strive to improve warehouse efficiency and reduce operational costs, many are turning to automation as a transformative solution. However, adopting automation without a clear, data-driven strategy can result in overinvestment, underutilization, and missed performance targets, all the while undermining the intended benefits. The key to unlocking the full potential of automation lies in rightsizing, which is the process of determining the optimal scale and integration of automated systems to meet specific operational needs.

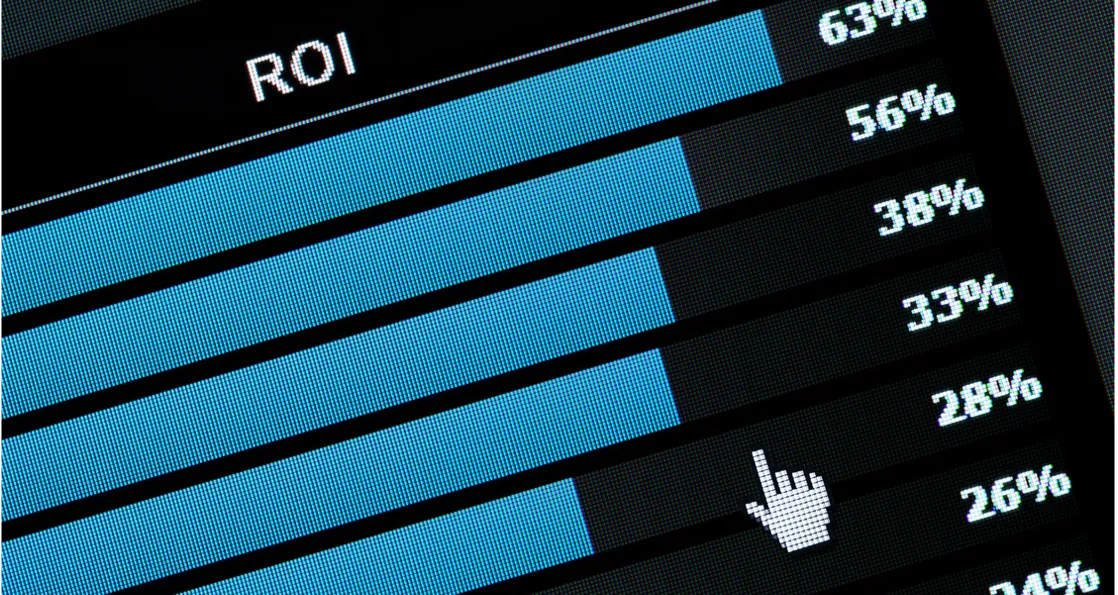

Rightsizing automation requires a strategic and structured approach. It begins with a comprehensive warehouse assessment that examines inventory profiles, throughput requirements, process flows, and space utilization. This is followed by a robust return on investment (ROI) analysis to evaluate the financial viability and operational impact of automation initiatives. Together, these steps ensure that automation investments are targeted, cost-effective, and aligned with long-term business goals.

Emerging technologies such as robotic picking systems, automated storage and retrieval systems (ASRS), autonomous mobile robots (AMRs), and advanced warehouse management software offer substantial gains in throughput, accuracy, and labor efficiency. Yet, due to the inherent complexity and variability of warehouse operations, a one-size-fits-all approach is rarely effective. A tailored solution, based on a clear understanding of a facility’s specific challenges and growth objectives, is essential.

This paper presents a proven methodology for rightsizing warehouse automation, grounded in two foundational steps: conducting a thorough warehouse assessment and performing a detailed ROI analysis. By identifying high-value opportunities, evaluating their impact on operational performance, and aligning them with strategic goals, organizations can implement automation solutions that deliver sustainable value and long-term success.

Conclusion

Rightsizing automation is a strategic imperative for warehouses seeking to enhance efficiency and competitiveness. By conducting a comprehensive warehouse assessment, businesses can identify high-value automation opportunities that align with operational needs. An effective ROI analysis ensures that these investments deliver sustainable financial returns.

Together, these steps empower companies to implement automation solutions that are neither excessive nor inadequate, but the right balance for long-term success.

With more than 30 years of logistics experience, including over two decades dedicated to engineering and operations, Randy specializes in transforming warehouse and fulfillment environments. As a seasoned Warehouse Engineer, he partners with businesses to uncover process improvements, design optimized layouts, and implement automation strategies that enhance throughput, accuracy, and overall performance. Guided by a passion for practical, scalable solutions, Randy works closely with customers to improve the flow of goods and the health of their bottom line.

Customer

Customer